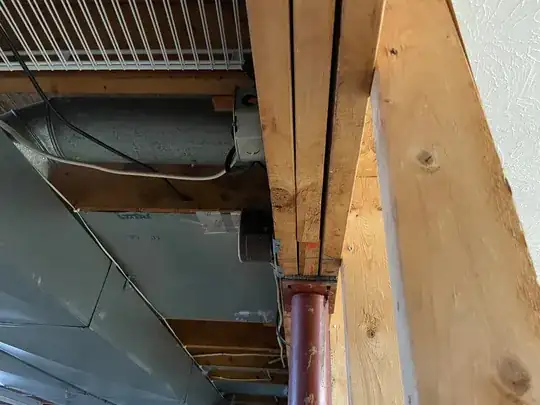

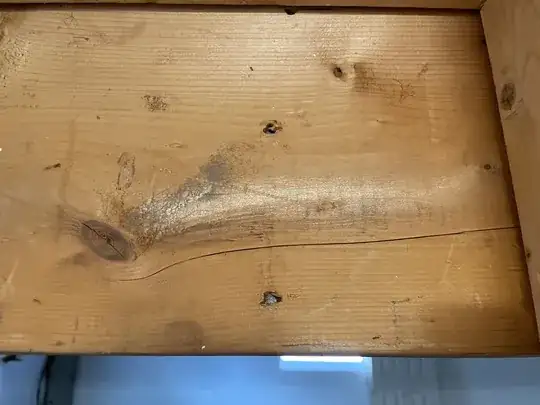

Even if it wasn't cracked its nailing schedule is awful.

FastenMaster TrussLOK Attaching Multi-ply Engineered Wood Beams, YouTube.

I like those but any structural screw is better than nails. The wood is old and dry; I'd move the minimum edge distance to more like 2.5" from the top and bottom. Which might mean only two rows and probably better if in a staggered pattern... every six inches? Check the spec sheets. Just remember that's for nice new lumber (LVLs actually) that won't split when you drive 1/4" lags into it without pre-drilling.

I use giant c-clamps to pull them together first, which the screws do a pretty good job of so don't let the clamp fall on your head or a tile floor. An impact driver is your friend here, the bigger the better. It wouldn't surprise me if it went in like that, given how it's cracked down the grain. Once properly laminated I wouldn't be concerned, even while thinking about what the one they hid in the middle must look like.

If you can move that wall to underneath like it should be, then it's a done deal. And that'd let you do the pattern right without studs in the way. Bonus points for plotting it out so the crack itself has minimum edge distance away from any fasteners that will end up near it.