You can rearrange your way out of your space shortage

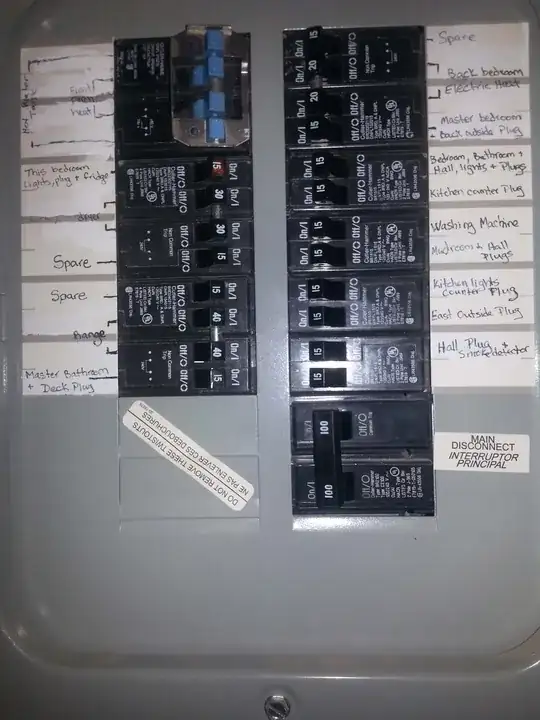

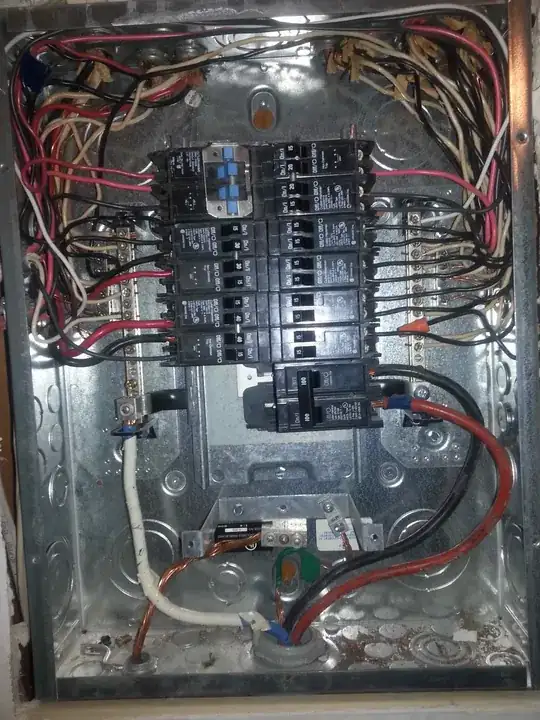

While the presence of the service barrier in your panel makes clear that those two bottom-left "spaces" are actually useless as they are on the wrong side of the barrier to be used for a branch circuit or feeder, all hope is not lost. With some rearranging of the existing breakers, and the replacement of one of them, we can make enough room in the panel to add a feeder breaker for a subpanel.

To do this, we start by moving the "This bedroom lights, plug, + fridge" circuit from its current home in space 5A two slots down to the existing spare in space 9A. Alongside this, we also move the "Master bedroom + back outside plug" circuit from its current home in space 4B down to the spare in space 12B, leaving us with spaces 5A/7B and 2A/4B as open pairs at this point.

From here, we can replace the existing dryer breaker with a DNPL220230; note that this is not a common-trip breaker, as CEC 14-302(b) (at least as of the 2015 CEC I was able to dig up) permits independent trip breakers in multi-wire branch circuits derived from 3-wire systems irrespective of the nature of the load. The two 30A (inner) poles in spaces 5B and 7A are used for the dryer (just as they were with the DNPL153015 that formerly occupied that spot), while the two 20A (outer) poles that now occupy spaces 5A and 7B get the "Back bedroom electric heater" circuit from 2B/4A moved to them. This allows the DNPL152015 that occupied spaces 2 and 4 to be removed, thus freeing room up for our feeder breaker, namely a BR2100.

You'll want to go big here, so you don't have to go back later

Now that we can run a feeder from here, we're going to take the liberty to install not one, but two panels as part of this. The first one will be a CBRPL130, installed near the existing panel in the house, and fed using insulated 1/0 Al wire, either in the form of individual wires in conduit (hot, hot, neutral, with metal conduit as the ground path) or in the form of an armored (TECK90) cable. This provides ample room for future expansion; if you wished to, you could even use a CBRPM140 for this new panel to allow the existing panel to be taken out of service at a future date.

Now that the space crisis has been averted for the long haul, we can then move onto feeding the shed. This is best done using #4 Al in PVC conduit with a separate grounding conductor in the conduit, with a 70A (BR270) feeder breaker protecting the wires to the shed. We then fit a CBRPM112 at the shed, with the main breaker serving as a structure disconnecting means, and a BR260 in it for the kiln circuit, as well as a BR115 each for lighting and general receptacles.

With both these new panels, the bonding strap or screw should be removed, as they are both subpanels, just like your existing panel. Furthermore, it is a good idea to use an inch-pound torque screwdriver or torque wrench to tighten all terminal screws to the manufacturer's specified torque; this prevents embarrassing connection failures down the road. The good news is that the shed does not need a grounding electrode of its own (it is grounded by the feeder equipment grounding conductor as per CEC 10-208(b)).

As to service capacity...

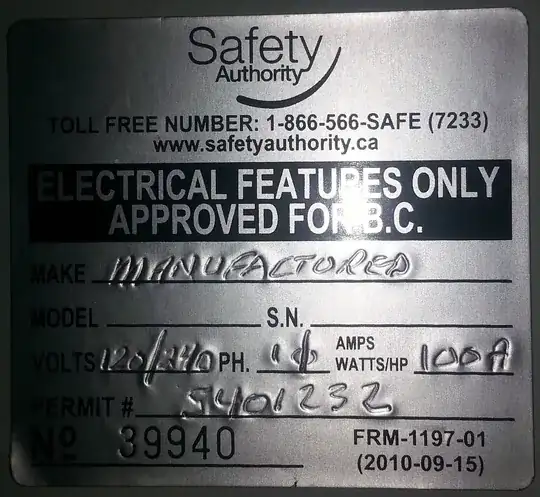

One of the other major substantive differences between the NEC and the CEC is in how they calculate service loads. Unlike the NEC, the CEC does not count kitchen and laundry small appliance branch circuits separately from the base lighting and appliance allowance, as set out in rule 8-200(1)(a)(i) and (ii). It also uses a 6kW baseline range load (vs the 8kW baseline used by the NEC) and applies an aggressive 25% demand factor to miscellaneous loads when a range is present, as per rule 8-200(1)(a)(vii).

It is this last factor that keeps the kiln from pushing your service calculations over the limit. When we run the numbers, we come up with 120m2 of floor area for your house, giving you an extra 1000W of base lighting load over the 5kW minimum, alongside 6kW for the range (assuming the range is not over 12kW), 3.75kW for the 3 baseboard heaters (with no demand factors applied), and a remaining unfactored load of 8kW (3kW water heater and 5kW dryer) that is demand factored down to 2kW. This totals out to 17.75kW, or 74A @ 240V; from here, we add the 11.52kW kiln at the same 25% miscellaneous-load demand factor as the dryer and water heater, putting us at 20.63kW, or 86A @ 240V, well within what your 100A service can handle.