I have a barstool that has lost several examples of the screw pictured below, and I do not have calipers to measure it precisely. The screw is pictured atop a U.S. quarter coin.

Since the condition of the screw is imperfect, I should mention that I think this is an example of an internal hex screw (I am new to this nomenclature).

The barstool from which this originated is very similar in appearance to this example sold by Lowes and this example featured on the Bed Bath & Beyond website.

EDIT 2023.09.06: I must thank everybody for the interest and advice and also apologize for the poor quality of the pictures I posted.

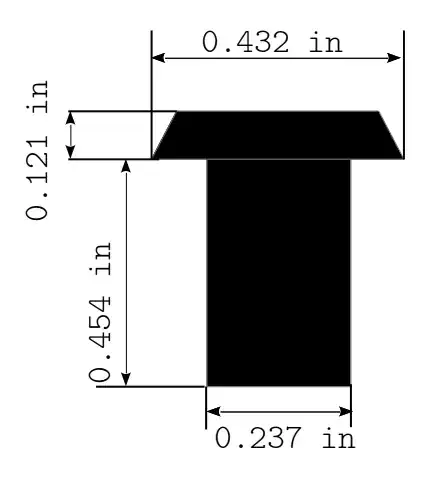

I know that I needn't stick to the exact same type of screw, but I thought that some people might still be curious what it is. I found some calipers at work, and the following (not-to-scale) diagram shows my measurements to three significant digits.

I did some novice-level research (search engine), and judging by examples I found, I suspect the following describe some qualitative features.

- Pan head

- Hex socket

- Black oxide finish

| Imperial measurement | Equivalent metric measurement (to 3 significant digits) |

|---|---|

| 0.432 in | 11.0 mm |

| 0.121 in | 3.07 mm |

| 0.454 in | 11.5 mm |

| 0.237 in | 6.02 mm |

Based on the finish and the examples I found online, I suspect that the 6.02 mm measurement should be interpreted as 6 mm and that this is an M6 screw. Combining this with what I saw available online, I suspect that this is an M6 x 12 mm screw.